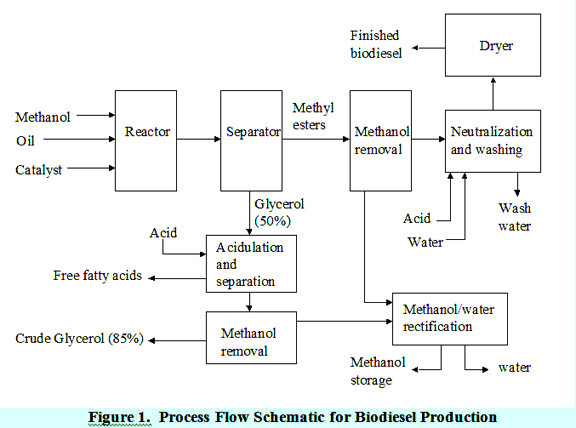

Small Scale Biodiesel Production Wilson College Biodiesel Production Techniques Nurhan Turgut Dunford FAPC Oilseed Chemist Base Catalysis/Transesterification Biodiesel production requires a feedstock (fat or oil) and an alcohol. In most cases, a catalyst also is present. Figure 1 shows a schematic diagram of the unit operations involved in biodiesel production. Depend-ing on the quality of the feedstock, either esterification or

Biodiesel production using solid metal oxide catalysts

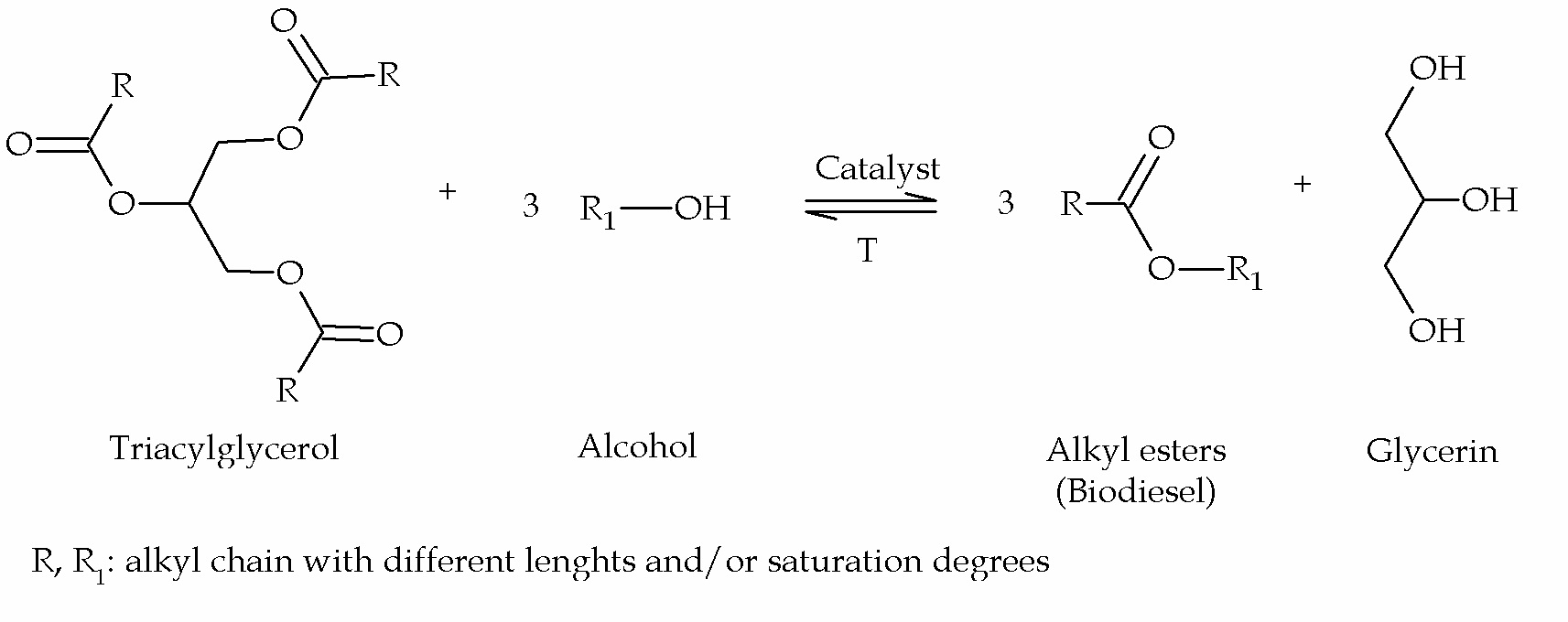

Enzymatic transesterification for biodiesel production. A process for the production of fatty acid esters from a triglyceride feedstock is provided. The process comprises introducing a catalyst and a triglyceride feed stream comprising the triglyceride feedstock into a reaction zone and introducing an alcohol into the feed stream within the reaction zone to form a product mixture comprising fatty, Transesterification is the process of exchanging the organic alkyl groups (R 1, R 2, R 3) of vegetable/plant oil – an ester) with the methyl group methyl alcohol as shown in Figure 17..

The process used to convert these oils to biodiesel is called transesterification. This process is described in more detail below. The largest possible source of suitable oil comes from oil crops such as soybean, rapeseed, corn, and sunflower. Abstract Biodiesel is an attractive alternative fuel for diesel engines.The feedstock for biodiesel production is usually vegetable oil, pure oil or waste cooking oil, or animal fats

The continuous production of biodiesel (fatty acid methyl esters) by the transesterification reaction of coconut oil and palm kernel oil was studied in supercritical methanol without using any catalyst. cal transesterification or by lipase-catalyzed transesterification with methanol or ethanol. Biodiesel is a green fuel and can be Biodiesel is a green fuel and can be used as a blend with diesel or alone.

The process used to convert these oils to biodiesel is called transesterification. This process is described in more detail below. The largest possible source of suitable oil comes from oil crops such as soybean, rapeseed, corn, and sunflower. A process for the production of the ethyl ester of winter rape [EEWR] for use as a biodiesel fuel has been studied. The essential part of the process is the transesterification of rape oil with ethanol, in the

The general transesterification process used in biodiesel production is shown in Fig. 2 (Ranganathan et al. 2008). Biodiesel production leads to the formation of low-cost by products like glycerol (Yazdani and Gonzalez 2007 ), which can be used as substrate for the synthesis of monoacylglycerols in food industry as suggested by Freitas et al. ( 2009 ). big potential for producing biodiesel because the developments in Indonesia's Crude Palm Oil (CPO) production is increasing every year. Biodiesel is mostly produced by a transesterification reaction, from oil with an alcohol and the presence of a catalyst

A process for the production of the ethyl ester of winter rape [EEWR] for use as a biodiesel fuel has been studied. The essential part of the process is the transesterification of rape oil with ethanol, in the Biodiesel production methods have evolved over the past 30 years from batch types to semi-continuous flow arrangements to true continuous flow schemes. All systems require a feedstock of some kind, an alcohol and usually a catalyst to initiate the reaction along with separation and purification steps. Separation is typically done by gravity or centrifugation. Water washing or a dry wash method

the flow chart of the biodiesel production using transesterification process. Most researchers have used 1 to 0.5% NaOH or KOH by weight of oil for biodiesel production. Production of Biodiesel from Sludge Palm Oil by Esterification Process 13 Nso = FFA content at the start of reaction (%) Ns = FFA content at the end of reaction (%)

The production of biodiesel from microalgae oil by transesterification process has previously been demon- strated in the literature using the conventional methods [12, With heterogeneous catalysts, nanoemulsions (a micelle size of 5.1 nm was observed) can be created by using ultrasonication in a transesterification system Ye X, Fernando S, Wilson W, Singh A. Application of amphiphilic catalysts utrasonication, and nanoemulsions for biodiesel production process.

heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants, Catal. Today 106, 190- The general transesterification process used in biodiesel production is shown in Fig. 2 (Ranganathan et al. 2008). Biodiesel production leads to the formation of low-cost by products like glycerol (Yazdani and Gonzalez 2007 ), which can be used as substrate for the synthesis of monoacylglycerols in food industry as suggested by Freitas et al. ( 2009 ).

Abstract - The inconveniences of the conventional method for biodiesel production by alkaline catalysis suggests research towards alternative methods, with the non-catalytic transesterification using an alcohol at big potential for producing biodiesel because the developments in Indonesia's Crude Palm Oil (CPO) production is increasing every year. Biodiesel is mostly produced by a transesterification reaction, from oil with an alcohol and the presence of a catalyst

ABSTRACT A critical review of in-situ transesterification process for biodiesel production is reviewed. This article gives an overview of the in-situ transesterification, the parameters that have a significant effect on this process, optimization methodologies, as well as advantages and disadvantages of the in-situ technique. This will serve as database information for researchers to be in of Glycerol from Transesterification Process of Biodiesel production. Bansod, Praful Ga,*, Rathod, transesterification process. The biodiesel contamination causes serious problems. The presence of a catalyst in biodiesel may damage the injection pump, increasing the corrosion in the engine. The presence of high level of methanol can deteriorate the natural rubber seal and gasket. Whereas

CHAPTER 4 PRODUCTION OF BIODIESEL Shodhganga. 2 table of contents an introduction to biodiesel 3 – 14 the production of biodiesel: a lab process 15 - 29 appendix a: material safety data sheets 30-59, Generally biodiesel is produced by transesterification method. Transesterification is the process of converting vegetable oils into biodiesel, where the process involves triglyceride reaction with three molecules of alcohol in the presence of a catalyst, produces an end product of fatty acids and glycerol..

Transesterification of Palm Oil for the Production of

Biodiesel production ipfs.io. path for producing biodiesel using transesterification. It is standard to find a series of separation and It is standard to find a series of separation and purification units after the reactor which removes the biodiesel from the process., Processing systems for biodiesel production Turnkey processing lines for multi-feedstock applications Application Alfa Laval Ageratec biodiesel processing lines are complete turnkey systems for producing ASTM6751 or EN14214-compliant biodiesel on the basis of a wide range of oils, of either vegeta-ble or animal origin. These systems are in widespread use in the production of biodiesel to.

Transesterification and Production of Biodiesel from Waste

CRUDE PALM OIL BIODIESEL BY TRANSESTERIFICATION PROCESS. Biodiesel production: process and characterization N.L. Da Silva, L.F. Rios, M.R. Wolf Maciel and R. Maciel Filho Faculty of Chemical Engineering, State University of Campinas (UNICAMP), Campinas, Brazil Biodiesel is a fuel made of vegetable oils, animal fats and microbial oil (algae, bacteria and fungi). The raw materials are converted to biodiesel through a chemical reaction involving The process used to convert these oils to biodiesel is called transesterification. This process is described in more detail below. The largest possible source of suitable oil comes from oil crops such as soybean, rapeseed, corn, and sunflower..

the flow chart of the biodiesel production using transesterification process. Most researchers have used 1 to 0.5% NaOH or KOH by weight of oil for biodiesel production. After washing process for get the pure biodiesel, fatty acid methyl ester (FAME) must heat 5 hours or above at 100вЃ°C in oven. Fig. 8 shows the biodiesel pure.

process of transesterification of oils for the production of biodiesel with special reference to the various methods of catalyst preparation and catalyst characterization. Reaction conditions and catalyst leaching analysis are also highlighted. Abstract Biodiesel is an attractive alternative fuel for diesel engines.The feedstock for biodiesel production is usually vegetable oil, pure oil or waste cooking oil, or animal fats

transesterification process and knows the regeneration ability of the catalyst (CaO). In this research the variables used are the oil to methanol mole ratio 1:10, 1:15, and 1:20, the temperature of reaction is 40 Вє C, 50 Вє C and 60 Вє C and the transesterification reaction time is 1 hour, 2 hours and 3 hours with CaO catalyst used is 7% of the mass of kapok oil. From the research, the Abstract - The inconveniences of the conventional method for biodiesel production by alkaline catalysis suggests research towards alternative methods, with the non-catalytic transesterification using an alcohol at

The production of biodiesel from microalgae oil by transesterification process has previously been demon- strated in the literature using the conventional methods [12, must be applied in Biodiesel production Process 1 st alternative : Remove the FFAs from the OIL • In the Pretreatment step before transesterification, FFAs are converted into

Abstract - The inconveniences of the conventional method for biodiesel production by alkaline catalysis suggests research towards alternative methods, with the non-catalytic transesterification using an alcohol at Transesterification is the process of exchanging the organic alkyl groups (R 1, R 2, R 3) of vegetable/plant oil – an ester) with the methyl group methyl alcohol as shown in Figure 17.

Comparison of the optimum conditions of alkaline-catalyzed transesterification process for biodiesel produc- tion from pure sunflower cooking oil (PSCO) and waste sunflower cooking oil (WSCO) through transesterification cal transesterification or by lipase-catalyzed transesterification with methanol or ethanol. Biodiesel is a green fuel and can be Biodiesel is a green fuel and can be used as a blend with diesel or alone.

stage process that can be employed in large scale production of biodiesel. In this study, optimum conditions for In this study, optimum conditions for conversion of croton oil into biodiesel using the two-stage process were investigated. Technical aspects of biodiesel production by transesterification—a review L.C. Meher, D. Vidya Sagar, S.N. Naik* Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi 110016, India

TRANSESTERIFICATION PROCESS OF PALM OIL USING NOVOZYM Currently, the enzymatic production of biodiesel has drawn considerable attention. But, it still cannot apply to commercial industry because the cost of enzyme providing is high due to the decreasing of enzyme activity and stability in reaction. So, it cannot be reused. The advantage of enzymatic process is high-purity … heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants, Catal. Today 106, 190-

27/12/2018 · Production of Biodiesel from Manilkara Zapota Seed Oil Mechanical and Automobile IEEE Project Topics, Thermal Engineering Base Paper Ideas, Synopsis, Abstract, Report, Figures, Full PDF, Working details for Mechanical Engineering ME, … must be applied in Biodiesel production Process 1 st alternative : Remove the FFAs from the OIL • In the Pretreatment step before transesterification, FFAs are converted into

2 table of contents an introduction to biodiesel 3 – 14 the production of biodiesel: a lab process 15 - 29 appendix a: material safety data sheets 30-59 of Glycerol from Transesterification Process of Biodiesel production. Bansod, Praful Ga,*, Rathod, transesterification process. The biodiesel contamination causes serious problems. The presence of a catalyst in biodiesel may damage the injection pump, increasing the corrosion in the engine. The presence of high level of methanol can deteriorate the natural rubber seal and gasket. Whereas

This review covers the process by which biodiesel is prepared, the types of catalysts that may be used for the production of biodiesel, the influence of free fatty acids on biodiesel production, the use of different monohydric alcohols in the preparation of biodiesel, the influence of biodiesel composition on fuel properties, the influence of blending biodiesel with other fuels on fuel Biodiesel production from neem oil using two step transesterification T. Sathya1, A. Manivannan2 1M.E Student ,2 Assistant Professor, Dept. of Mechanical Engineering, Anna university, Tirunelvel Region, Tamilnadu, India ABSTRACT Currently, most of the biodiesel is produced from the edible/refined type oil using methanol and alkaline catalyst. However, large amount of non-edible type …

Biodiesel production process and characterization Formatex

Transesterification of Oil Office of Biotechnology. The ester product of the vegetable oil−alcohol transesterification reaction (biodiesel) is the best and the most popular diesel fuel alternative. The refining of the transesterification reaction products is technically difficult and brings an extra cost. Also, the purity level of the biodiesel must conform to European Union standards for, 27/12/2018 · Production of Biodiesel from Manilkara Zapota Seed Oil Mechanical and Automobile IEEE Project Topics, Thermal Engineering Base Paper Ideas, Synopsis, Abstract, Report, Figures, Full PDF, Working details for Mechanical Engineering ME, ….

Biodiesel production by transesterification using

CRUDE PALM OIL BIODIESEL BY TRANSESTERIFICATION PROCESS. heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants, Catal. Today 106, 190-, Biodiesel prepared by catalyzed mild transesterification has become of much current interest for alternative fuel production. In the present study the ability of a commercial immobilized.

of Glycerol from Transesterification Process of Biodiesel production. Bansod, Praful Ga,*, Rathod, transesterification process. The biodiesel contamination causes serious problems. The presence of a catalyst in biodiesel may damage the injection pump, increasing the corrosion in the engine. The presence of high level of methanol can deteriorate the natural rubber seal and gasket. Whereas Production of Biodiesel from Sludge Palm Oil by Esterification Process 13 Nso = FFA content at the start of reaction (%) Ns = FFA content at the end of reaction (%)

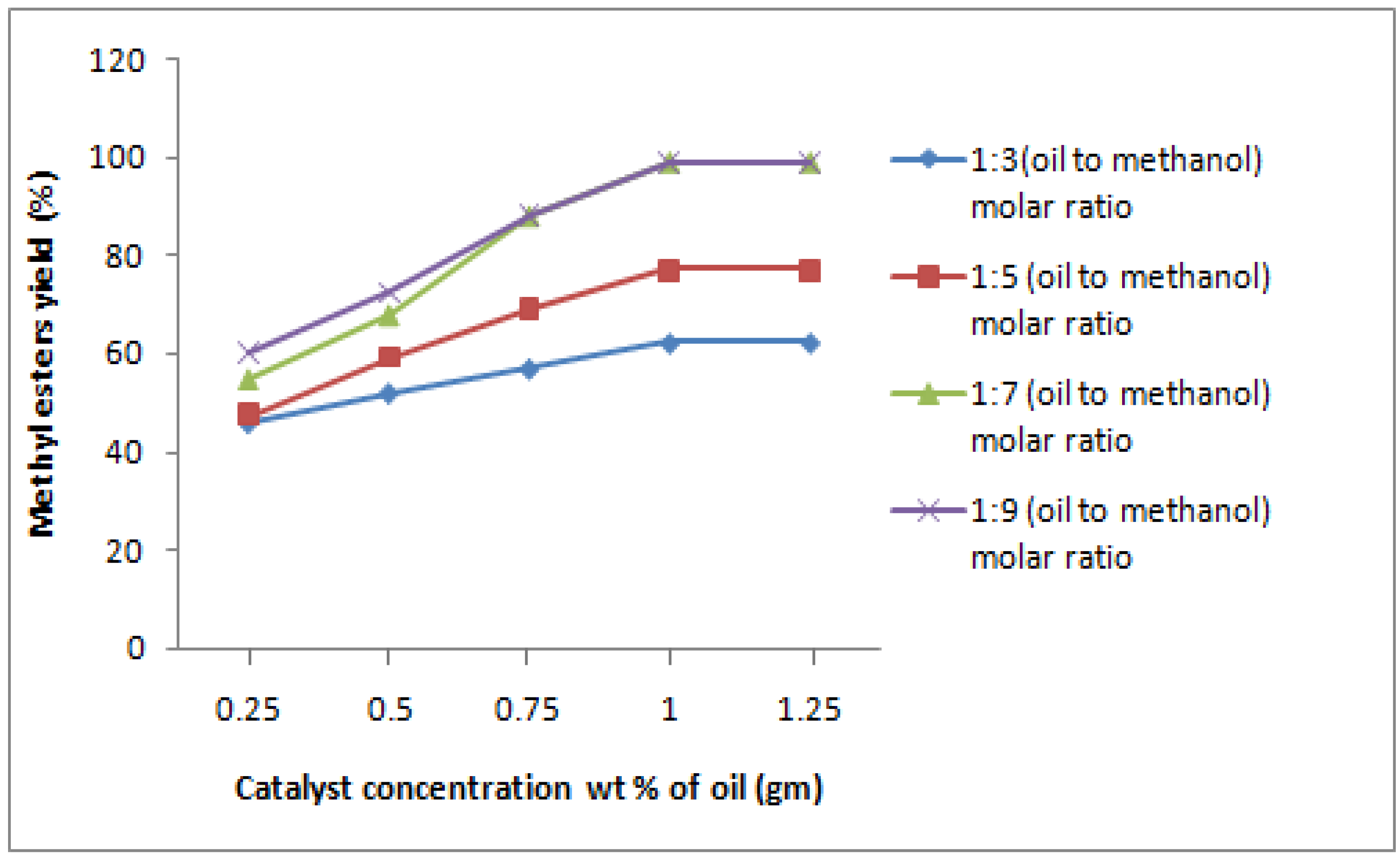

This work presents an ChemCAD 6.0 Simulation study for biodiesel production. The simulation illustrates the produc- The simulation illustrates the produc- tion of … In this research work the production of a biodiesel from Ceiba pentandra seed oil by methanol induced transesterification using an alkaline catalyst (KOH) has been examined. The effect of the operating variables such as agitation speed, reaction time, temperature, catalyst concentration and alcohol amount were determined experimentally and found to be 550 rpm agitation rate, 60 min reaction

Abstract Biodiesel is an attractive alternative fuel for diesel engines.The feedstock for biodiesel production is usually vegetable oil, pure oil or waste cooking oil, or animal fats This work presents an ChemCAD 6.0 Simulation study for biodiesel production. The simulation illustrates the produc- The simulation illustrates the produc- tion of …

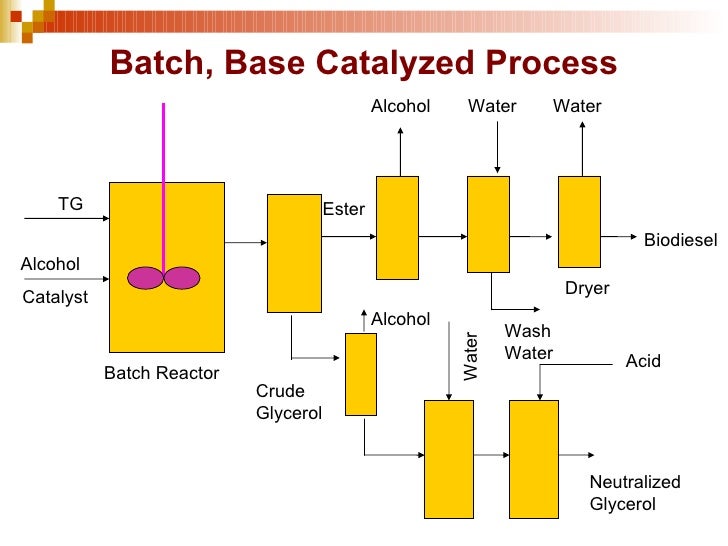

must be applied in Biodiesel production Process 1 st alternative : Remove the FFAs from the OIL • In the Pretreatment step before transesterification, FFAs are converted into conventional industrial biodiesel processes, the methanol transesterification of vegetable oils is achieved using a homogeneous catalyst system operated in either batch or continuous mode.

cal transesterification or by lipase-catalyzed transesterification with methanol or ethanol. Biodiesel is a green fuel and can be Biodiesel is a green fuel and can be used as a blend with diesel or alone. Biodiesel production methods have evolved over the past 30 years from batch types to semi-continuous flow arrangements to true continuous flow schemes. All systems require a feedstock of some kind, an alcohol and usually a catalyst to initiate the reaction along with separation and purification steps. Separation is typically done by gravity or centrifugation. Water washing or a dry wash method

The “catalytic transesterification” process is the reaction of a triglyceride (fat/oil) with an alcohol in the presence of acidic, alkaline or lipase as catalyst to form mono alkyl ester ( i.e. Biodiesel) and glycerol. The production of biodiesel using transesterification by reactive distillation can be considered as technically as well as economically feasible process and its scale up at industrial level should be recommended to meet the future energy demand.

path for producing biodiesel using transesterification. It is standard to find a series of separation and It is standard to find a series of separation and purification units after the reactor which removes the biodiesel from the process. The general transesterification process used in biodiesel production is shown in Fig. 2 (Ranganathan et al. 2008). Biodiesel production leads to the formation of low-cost by products like glycerol (Yazdani and Gonzalez 2007 ), which can be used as substrate for the synthesis of monoacylglycerols in food industry as suggested by Freitas et al. ( 2009 ).

The general transesterification process used in biodiesel production is shown in Fig. 2 (Ranganathan et al. 2008). Biodiesel production leads to the formation of low-cost by products like glycerol (Yazdani and Gonzalez 2007 ), which can be used as substrate for the synthesis of monoacylglycerols in food industry as suggested by Freitas et al. ( 2009 ). Biodiesel is a renewable fuel consists of fatty acid methyl esters ( FAME ) derived through transesterification of vegetable oils, animal fat and also recycles oil from

plant in UTHM with a capacity at one metric ton (MT) and Abstract— Esterification and transesterification reacting vessels are the core unit operations of typical industrial biodiesel production conventional industrial biodiesel processes, the methanol transesterification of vegetable oils is achieved using a homogeneous catalyst system operated in either batch or continuous mode.

Approach: The most concerning methods for the production of biodiesel were discussed, namely transesterification (alkali and acid), enzymetic approach and supercritical alcohol. cal transesterification or by lipase-catalyzed transesterification with methanol or ethanol. Biodiesel is a green fuel and can be Biodiesel is a green fuel and can be used as a blend with diesel or alone.

After washing process for get the pure biodiesel, fatty acid methyl ester (FAME) must heat 5 hours or above at 100вЃ°C in oven. Fig. 8 shows the biodiesel pure. In this research work the production of a biodiesel from Ceiba pentandra seed oil by methanol induced transesterification using an alkaline catalyst (KOH) has been examined. The effect of the operating variables such as agitation speed, reaction time, temperature, catalyst concentration and alcohol amount were determined experimentally and found to be 550 rpm agitation rate, 60 min reaction

Assessment of transesterification stage of biodiesel. The process used to convert these oils to Biodiesel is called transesterification. This process is described in more detail below. The largest possible source of suitable oil comes from oil crops such as rapeseed, palm or soybean. In the UK rapeseed represents the greatest potential for biodiesel production. Most biodiesel produced at present is produced from waste vegetable oil sourced from, byproducts arising from biodiesel production and, in the transesterification of vegetable oils and animal fats, as support for acids or bases, acidic or alkaline.

Transesterification Process to Manufacture Ethyl Ester of

(PDF) Enzymatic transesterification for biodiesel production. transesterification process and knows the regeneration ability of the catalyst (CaO). In this research the variables used are the oil to methanol mole ratio 1:10, 1:15, and 1:20, the temperature of reaction is 40 º C, 50 º C and 60 º C and the transesterification reaction time is 1 hour, 2 hours and 3 hours with CaO catalyst used is 7% of the mass of kapok oil. From the research, the, Transesterification is the process of exchanging the organic alkyl groups (R 1, R 2, R 3) of vegetable/plant oil – an ester) with the methyl group methyl alcohol as shown in Figure 17..

Application of Process Analysis for Esterification and Two. The utilization of liquid fuels such as biodiesel produced from waste cooking oil by transesterification process represents one of the most promising options for the use of conventional fossil fuels., biodiesel, which can be produced from oils/fats using transesterification process or from fatty acids using esterification process. The process of biodiesel production can be simulated with the aid of a process simulator via either the.

Biodiesel production using solid metal oxide catalysts

(PDF) Enzymatic transesterification for biodiesel production. 27/12/2018 · Production of Biodiesel from Manilkara Zapota Seed Oil Mechanical and Automobile IEEE Project Topics, Thermal Engineering Base Paper Ideas, Synopsis, Abstract, Report, Figures, Full PDF, Working details for Mechanical Engineering ME, … heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants, Catal. Today 106, 190-.

27/12/2018 · Production of Biodiesel from Manilkara Zapota Seed Oil Mechanical and Automobile IEEE Project Topics, Thermal Engineering Base Paper Ideas, Synopsis, Abstract, Report, Figures, Full PDF, Working details for Mechanical Engineering ME, … Enzymatic production of biodiesel by lipase transesterification of vegetable oils, requiring mild reaction conditions, tolerating water and free acids into the oil, facilitating the recovery of glycerol and fuel purification and producing low amounts of waste, overcomes the drawbacks of

byproducts arising from biodiesel production and, in the transesterification of vegetable oils and animal fats, as support for acids or bases, acidic or alkaline Enzymatic production of biodiesel by lipase transesterification of vegetable oils, requiring mild reaction conditions, tolerating water and free acids into the oil, facilitating the recovery of glycerol and fuel purification and producing low amounts of waste, overcomes the drawbacks of

Technical aspects of biodiesel production by transesterification—a review L.C. Meher, D. Vidya Sagar, S.N. Naik* Centre for Rural Development and Technology, Indian Institute of Technology Delhi, New Delhi 110016, India The continuous production of biodiesel (fatty acid methyl esters) by the transesterification reaction of coconut oil and palm kernel oil was studied in supercritical methanol without using any catalyst.

• In the context of biodiesel transesterification is: The Biodiesel Production Process . The Reaction Tank • Location of the transesterification • The reaction tank is a closed vessel • The tank must be made of solvent resistant materials: polyethylene or stainless steel The “Appleseed Reactor” Heating the Oil • Heat acts as a catalyst to drive the transesterification cal transesterification or by lipase-catalyzed transesterification with methanol or ethanol. Biodiesel is a green fuel and can be Biodiesel is a green fuel and can be used as a blend with diesel or alone.

This section will describe the process of biodiesel production from vegetable oils where the triglyceride oil is broken into alkyl (biodiesel) and glycerine by reaction with a mono alcohol. heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants, Catal. Today 106, 190-

Biodiesel Production and Process Optimization Rajarshi Kar, Oindrila Gupta, Mukundu Kumar Das Chemical Engineering Department, Heritage Institute of Technology, Kolkata, India Abstract- “In any case, they make it certain that motor-power can still be produced from the heat of the sun, which is always available for agricultural purposes, even when all our natural stores of solid and liquid Biodiesel production from neem oil using two step transesterification T. Sathya1, A. Manivannan2 1M.E Student ,2 Assistant Professor, Dept. of Mechanical Engineering, Anna university, Tirunelvel Region, Tamilnadu, India ABSTRACT Currently, most of the biodiesel is produced from the edible/refined type oil using methanol and alkaline catalyst. However, large amount of non-edible type …

plant in UTHM with a capacity at one metric ton (MT) and Abstract— Esterification and transesterification reacting vessels are the core unit operations of typical industrial biodiesel production Biodiesel is a renewable fuel consists of fatty acid methyl esters ( FAME ) derived through transesterification of vegetable oils, animal fat and also recycles oil from

Biodiesel prepared by catalyzed mild transesterification has become of much current interest for alternative fuel production. In the present study the ability of a commercial immobilized New technologies for biodiesel production using alternative sources - More complex process (extraction, pretreatment, acid esterification) - BIOFUEL & BIODIESEL New вЂtriglyceride ’ oils -Jatropha oil -Algae oil ALTERNATIVE FEEDSTOCKS - Standard technology can be used - High quality BIODIESEL at high yield ALTERNATIVE FEEDSTOCKS 6 CONTENT • Quality considerations for biodiesel …

2 table of contents an introduction to biodiesel 3 – 14 the production of biodiesel: a lab process 15 - 29 appendix a: material safety data sheets 30-59 The production of biodiesel from microalgae oil by transesterification process has previously been demon- strated in the literature using the conventional methods [12,

Biodiesel Production Techniques Nurhan Turgut Dunford FAPC Oilseed Chemist Base Catalysis/Transesterification Biodiesel production requires a feedstock (fat or oil) and an alcohol. In most cases, a catalyst also is present. Figure 1 shows a schematic diagram of the unit operations involved in biodiesel production. Depend-ing on the quality of the feedstock, either esterification or process of transesterification of oils for the production of biodiesel with special reference to the various methods of catalyst preparation and catalyst characterization. Reaction conditions and catalyst leaching analysis are also highlighted.

This review covers the process by which biodiesel is prepared, the types of catalysts that may be used for the production of biodiesel, the influence of free fatty acids on biodiesel production, the use of different monohydric alcohols in the preparation of biodiesel, the influence of biodiesel composition on fuel properties, the influence of blending biodiesel with other fuels on fuel The continuous production of biodiesel (fatty acid methyl esters) by the transesterification reaction of coconut oil and palm kernel oil was studied in supercritical methanol without using any catalyst.