Process modeling and simulation chemical engineering pdf East Gwillimbury

Modeling and simulation in chemical engineering pdf Modeling and Simulation of a Benzene Recovery Process by Extractive Distillation 285 Brazilian Journal of Chemical Engineering Vol. 32, No. 01, pp. 283 - 291, January - March, 2015

PROCESS MODELING AND COMPARISON STUDY OF ACID GAS

Best Reference Books Modeling and Simulation in Process. Process Modeling and Simulation for Chemical Engineers: Theory and Practice В© 2017 John Wiley & Sons Ltd, Presents and solves chemical engineering problems in an industrial context. Emphasis is placed on the integration of fundamental concepts with approaches of process design. Problems are emphasized that demand synthesis, economic analysis, and process design..

Process Modeling and Simulation for Chemical Engineers: Theory and Practice В© 2017 John Wiley & Sons Ltd Modeling and simulation also lets you propose some designs and process conditions, and then tinker with them or optimize them.\аµњз€Ђе±ІA lot can be considered and achieved before proceeding to the expensive stage of building prototypes or deploying directly toе°Ќ manufacture, through using simulations.

While the chemical process engineers model the complex thermodynamic and kinetic interactions within the plant, controls engineers model the control algorithms. The plant and its control system can then be tested in dynamic and steady-state closed-loop simulations. Process Systems Engineering, 2. Modeling and Simulation RAFIQUL GANI, Technical University of Denmark, Department of Chemical and Biochemical Engineering, Lyngby, Denmark

B. WAYNE BEQUETTE is Professor of Chemical Engineering at Rensselaer Polytechnic Institute. His teaching and research interests are in the areas of process systems and control engineering for biomedical systems, pharmaceuticals, chromatography, and complex chemical processes. Materials & Chemical Processing. Simulation solutions for the process industry is helping companies with significant engineering improvement in their asset- and process …

Modeling and Simulation for Chemical Engineers: Theory and Practice begins with an introduction to the terminology of process modeling and simulation. Chapters 2 and 3 cover fundamental and constitutive relations, while Chapter 4 on model formulation builds on these relations. Chapters 5 and 6 PROCESS MODELING AND SIMULATION • What is the cost of goods? • What are the cost sensitive operating parameters? • What are the assumptions and where is the uncertainty? • Where are the economic hot spots? • Where should one focus R&D? • What is the impact of process change on cost and quality? • Are there alternative processes? • Where are the process bottlenecks? • How can

current simulation technologies can effectively support the design process. For simulation-based design, modeling For simulation-based design, modeling languages and simulation environments must take into account the special characteristics of the design process. New PDF release: Wind Turbine Airfoils and Blades: Optimization Design Theory. Wind Turbine Airfoils and Blades introduces new principles within the layout of wind turbine airfoils and blades in accordance with practical imperative concept and the finite aspect process, observed by means of effects from wind tunnel checking out.

PROCESS MODELING AND SIMULATION • What is the cost of goods? • What are the cost sensitive operating parameters? • What are the assumptions and where is the uncertainty? • Where are the economic hot spots? • Where should one focus R&D? • What is the impact of process change on cost and quality? • Are there alternative processes? • Where are the process bottlenecks? • How can 2 . 1 Introduction . Integrating dynamic simulation into the chemical engineering curriculum has aroused considerable interest due to the increasing use of simulators in industry for process design, control, training and

Mathematical Modeling in Chemical Engineering A solid introduction to mathematical modeling for a range of chemical engineering applications,coveringmodelformulation,simplification,andvalidation.Itexplainshow This of Process Modeling and Simulation paper is original examination paper of the regular course of eighth semester students of Bachelor of Engineering in Chemical Engineering branch course for the year 2010. Question paper is attached in PDF file format you can download it and able to view it with the help of Acrobat Reader.

Download process modeling and simulation for chemical engineers or read online books in PDF, EPUB, Tuebl, and Mobi Format. Click Download or Read Online button to get process modeling and simulation for chemical engineers book now. This book offers a comprehensive coverage of process simulation and flowsheeting, useful for undergraduate students of Chemical Engineering and Process Engineering as theoretical and practical support in Process Design, Process Simulation, Process Engineering, Plant Design, and Process Control courses.

The area of Modelling/Simulation characterizes a generation of chemical engineers associated with the Second Paradigm of Chemical Engineering. Today, simulation tasks can be simplified with the availability of friendly user software; the question of validation of results remains and in principle more time will be available to analyze results. B. WAYNE BEQUETTE is Professor of Chemical Engineering at Rensselaer Polytechnic Institute. His teaching and research interests are in the areas of process systems and control engineering for biomedical systems, pharmaceuticals, chromatography, and complex chemical processes.

Process Control: Modeling, Design and Simulation Prentice Hall, Upper Saddle River, NJ (2003). B. Wayne Bequette (19 December 2001) Preface There are a variety of courses in a standard chemical engineering curriculum, ranging from the This book offers a comprehensive coverage of process simulation and flowsheeting, useful for undergraduate students of Chemical Engineering and Process Engineering as theoretical and practical support in Process Design, Process Simulation, Process Engineering, Plant Design, and Process Control courses.

Why Use Process Simulation?. Dynamic Process Simulation aspects of chemical engineering. It is this analysis, design, and implementation of control systems that facilitate the design of the objectives of process safety, production rates, and product quality. Chemical engineers not only need to develop a working control strategy, but also design a plant that is inherently easy to control. Using a dynamic simulator will, Download modeling and simulation in chemical engineering or read online here in PDF or EPUB. Please click button to get modeling and simulation in chemical engineering book now. All books are in clear copy here, and all files are secure so don't worry about it..

Why Use Process Simulation?

Luyben W. L. Process Modeling Simulation and Control. B. WAYNE BEQUETTE is Professor of Chemical Engineering at Rensselaer Polytechnic Institute. His teaching and research interests are in the areas of process systems and control engineering for biomedical systems, pharmaceuticals, chromatography, and complex chemical processes., This book offers a comprehensive coverage of process simulation and flowsheeting, useful for undergraduate students of Chemical Engineering and Process Engineering as theoretical and practical support in Process Design, Process Simulation, Process Engineering, Plant Design, and Process Control courses..

Best Reference Books Modeling and Simulation in Process. Process Control: Modeling, Design and Simulation Prentice Hall, Upper Saddle River, NJ (2003). B. Wayne Bequette (19 December 2001) Preface There are a variety of courses in a standard chemical engineering curriculum, ranging from the, Mathematical Modeling in Chemical Engineering A solid introduction to mathematical modeling for a range of chemical engineering applications,coveringmodelformulation,simplification,andvalidation.Itexplainshow.

Modeling and Simulation Move Forward Chemical

NPTEL Phase II Chemical Engineering - Process Modelling. Process simulation is the representation of a chemical process by a mathematical model, which is then solved to obtain information about the performance of the chemical process (Motard et al., 1975). It is also known as process flowsheeting . https://en.m.wikipedia.org/wiki/Business_process_modeling Limitations of simulation o Lack of good data and knowledge of process mechanism. o Character of the computational tools o the danger of forgetting the assumptions mode in modeling the process . Fundamental of chemical engineering ..

Modeling and Simulation of a Benzene Recovery Process by Extractive Distillation 285 Brazilian Journal of Chemical Engineering Vol. 32, No. 01, pp. 283 - 291, January - March, 2015 This of Process Modeling and Simulation paper is original examination paper of the regular course of eighth semester students of Bachelor of Engineering in Chemical Engineering branch course for the year 2010. Question paper is attached in PDF file format you can download it and able to view it with the help of Acrobat Reader.

Process simulation Process simulation software can be used in a variety of ways. One method is “front-end engineering” in which it serves as an aid when designing a new process or re-designing an existing one. “In these applications, the software is used to provide an engineering analysis that will help users find ways to improve the process or increase throughput efficiency,” explains Modelling and Simulation in Chemical Engineering: Tools for Process Innovation AlГrio E. Rodrigues LSRE DEQ FEUP ESCAPE-14 Lisbon, Portugal 17 MAY 2004 Modelling and Simulation in Chemical Engineering: Tools for Process Innovation A. E. Rodrigues ESCAPE-14 May 16-19, 2004 Fundação Calouste Gulbenkian Lisbon, Portugal. Modelling and Simulation in Chemical Engineering…

Chemical Process Simulation The objective of this course is to provide the background needed by the chemical engineers to carry out computer-aided analyses of large-scale chemical processes. Major concern will fall on steady-state processes with hands on experiences on ChemCad simulator (CC-5). CAD and the Structure of Design Process ANALYSIS Material &Energy balances Equip. Sizing and … Materials & Chemical Processing. Simulation solutions for the process industry is helping companies with significant engineering improvement in their asset- and process …

Process Systems Engineering, 2. Modeling and Simulation RAFIQUL GANI, Technical University of Denmark, Department of Chemical and Biochemical Engineering, Lyngby, Denmark modeling and simulation in chemical engineering pdf Once a process is well understood, modeling and simulations are used to optimize.A description of the use microeconomia y macroeconomia pdf of computer aided modeling and simulation in the development, integration and optimization of industrial

Dynamic Process Simulation aspects of chemical engineering. It is this analysis, design, and implementation of control systems that facilitate the design of the objectives of process safety, production rates, and product quality. Chemical engineers not only need to develop a working control strategy, but also design a plant that is inherently easy to control. Using a dynamic simulator will In this work, the industrial scale SMB process is investigated from modeling, simulation, and optimization points of view, using experimentally measured xylene adsorption equilibrium and kinetics

Process simulation is the representation of a chemical process by a mathematical model, which is then solved to obtain information about the performance of the chemical process (Motard et al., 1975). It is also known as process flowsheeting . This book offers a comprehensive coverage of process simulation and flowsheeting, useful for undergraduate students of Chemical Engineering and Process Engineering as theoretical and practical support in Process Design, Process Simulation, Process Engineering, Plant Design, and Process Control courses.

PROCESS MODELING AND SIMULATION Course Code: 13CH1122 L T P C 4103 Course Educational Objectives: This course introduces the student the following aspects. Present fundamental laws in developing model equations. Understand various chemical engineering systems. Mathematical models used for solving problems. Course Outcomes: After completion of this course the student … New PDF release: Wind Turbine Airfoils and Blades: Optimization Design Theory. Wind Turbine Airfoils and Blades introduces new principles within the layout of wind turbine airfoils and blades in accordance with practical imperative concept and the finite aspect process, observed by means of effects from wind tunnel checking out.

Modeling and Simulation for Chemical Engineers: Theory and Practice begins with an introduction to the terminology of process modeling and simulation. Chapters 2 and 3 cover fundamental and constitutive relations, while Chapter 4 on model formulation builds on these relations. Chapters 5 and 6 introduce the advanced techniques of model transformation and simplification. Chapter 7 deals with Companion in Chemical Engineering (CinChE): An Instructional Supplement and Chemical Process Simulation and the Aspen HYSYS Software — support a team-oriented and problem- based-learning environment for the introductory course in chemical engineering.

Process Modelling and Simulation in Chemical, Biochemical and Environmental Engineering explores effective modeling and simulation approaches for solving equations. Using a systematic treatment of model development and simulation studies for chemical, biochemical, and environmental processes, this book explains the simplification of a complicated process at various levels with the help of a Process simulation Process simulation software can be used in a variety of ways. One method is “front-end engineering” in which it serves as an aid when designing a new process or re-designing an existing one. “In these applications, the software is used to provide an engineering analysis that will help users find ways to improve the process or increase throughput efficiency,” explains

Process Analysis And Simulation Pdf download process analysis and simulation in chemical engineering process analysis and simulation pdf process capability analysis: an … modeling and simulation in chemical engineering Professor of Chemical Engineering and Co-Director of the Process Modeling and.Modelling and Simulation in Chemical Engineering. modelling and simulation in thermal and chemical engineering pdf Download.pdf.ESCAPE-14 mg75q2ys50 pdf Lisbon, Portugal.

2 . 1 Introduction . Integrating dynamic simulation into the chemical engineering curriculum has aroused considerable interest due to the increasing use of simulators in industry for process design, control, training and Dynamic Process Simulation aspects of chemical engineering. It is this analysis, design, and implementation of control systems that facilitate the design of the objectives of process safety, production rates, and product quality. Chemical engineers not only need to develop a working control strategy, but also design a plant that is inherently easy to control. Using a dynamic simulator will

ECRIRE UNE NOUVELLE FANTASTIQUE Cette séquence s’inscrit dans le cadre d’un concours organisé par le département des Hauts-de-Seine : il s’agissait d’écrire une nouvelle sur le thème du jeu. La nouvelle fantastique exemple pdf Sahanatien Page 1 of 2. La nouvelle au XIXème siècle, texte 1 LA NOUVELLE FANTASTIQUE La main d'écorché1 Il y a huit mois environ, un de mes amis, Louis R..., avait réuni, un soir, quelques camarades de collège ; nous buvions

Theoretical Chemical Engineering Modeling and Simulation

NPTEL Phase II Chemical Engineering - Process Modelling. PROCESS MODELING AND COMPARISON STUDY OF ACID GAS REMOVAL UNIT BY USING DIFFERENT AQUEOUS AMINES FLORENCE WEDNNA SANGGIE A thesis submitted in fulfillment of the requirements for the award of the degree of Bachelor of Chemical Engineering (Gas Technology) Faculty of Chemical & Natural Resources Engineering Universiti Malaysia Pahang April 2011. v …, Process Modeling and Simulation for Chemical Engineers: Theory and Practice © 2017 John Wiley & Sons Ltd.

Modeling and Simulation Go Beyond Design Chemical

Chemical Product and Process Modeling. B. WAYNE BEQUETTE is Professor of Chemical Engineering at Rensselaer Polytechnic Institute. His teaching and research interests are in the areas of process systems and control engineering for biomedical systems, pharmaceuticals, chromatography, and complex chemical processes., Modelling and Simulation in Chemical Engineering: Tools for Process Innovation AlГrio E. Rodrigues LSRE DEQ FEUP ESCAPE-14 Lisbon, Portugal 17 MAY 2004 Modelling and Simulation in Chemical Engineering: Tools for Process Innovation A. E. Rodrigues ESCAPE-14 May 16-19, 2004 Fundação Calouste Gulbenkian Lisbon, Portugal. Modelling and Simulation in Chemical Engineering….

The purpose of this book is to convey to undergraduate students an understanding of those areas of process control that all chemical engineers need to know. The presentation is concise, readable and restricted to only essential elements. The methods presented have been successfully applied in industry to solve real problems. Analysis of Dynamic Process Simulation aspects of chemical engineering. It is this analysis, design, and implementation of control systems that facilitate the design of the objectives of process safety, production rates, and product quality. Chemical engineers not only need to develop a working control strategy, but also design a plant that is inherently easy to control. Using a dynamic simulator will

Download.pdf.Chemical Engineering, Process Modelling and Simulation.Process Systems Engineering, 2. modeling and simulation in chemical engineering roger e frank's download RAFIQUL message authentication code pdf GANI, Technical University of Denmark, Department of Chemical … The Process Modeling and Simulation of Chemical engineering processes has attracted the attention of scientists and engineers for many decades and is still a subject of major importance for the knowledge of unitary processes of transport and kinetics.

modeling and simulation in chemical engineering Professor of Chemical Engineering and Co-Director of the Process Modeling and.Modelling and Simulation in Chemical Engineering. modelling and simulation in thermal and chemical engineering pdf Download.pdf.ESCAPE-14 mg75q2ys50 pdf Lisbon, Portugal. PROCESS MODELING AND COMPARISON STUDY OF ACID GAS REMOVAL UNIT BY USING DIFFERENT AQUEOUS AMINES FLORENCE WEDNNA SANGGIE A thesis submitted in fulfillment of the requirements for the award of the degree of Bachelor of Chemical Engineering (Gas Technology) Faculty of Chemical & Natural Resources Engineering Universiti Malaysia Pahang April 2011. v …

Limitations of simulation o Lack of good data and knowledge of process mechanism. o Character of the computational tools o the danger of forgetting the assumptions mode in modeling the process . Fundamental of chemical engineering . Modeling in Chemical Engineering 103 The concept of similarity extends to many characteristics besides geome-try. For example, in aeronautical engineering it may be specified that the mass

Modeling and Simulation for Chemical Engineers: Theory and Practice begins with an introduction to the terminology of process modeling and simulation. Chapters 2 and 3 cover fundamental and constitutive relations, while Chapter 4 on model formulation builds on these relations. Chapters 5 and 6 While the chemical process engineers model the complex thermodynamic and kinetic interactions within the plant, controls engineers model the control algorithms. The plant and its control system can then be tested in dynamic and steady-state closed-loop simulations.

Process Analysis And Simulation Pdf download process analysis and simulation in chemical engineering process analysis and simulation pdf process capability analysis: an … Process simulation is the representation of a chemical process by a mathematical model, which is then solved to obtain information about the performance of the chemical process (Motard et al., 1975). It is also known as process flowsheeting .

To introduce the methods and techniques of first principles modelling of plant and process dynamics. To develop a feel for the dynamics of a variety of process elements and systems. To understand the structure of plants and processes in terms of controlled, manipulated and disturbance variables. Modeling in Chemical Engineering 103 The concept of similarity extends to many characteristics besides geome-try. For example, in aeronautical engineering it may be specified that the mass

PROCESS MODELING AND COMPARISON STUDY OF ACID GAS REMOVAL UNIT BY USING DIFFERENT AQUEOUS AMINES FLORENCE WEDNNA SANGGIE A thesis submitted in fulfillment of the requirements for the award of the degree of Bachelor of Chemical Engineering (Gas Technology) Faculty of Chemical & Natural Resources Engineering Universiti Malaysia Pahang April 2011. v … It is our opinion that process engineering services are no longer adequate or complete without the presence of comprehensive process simulation software and chemical engineers highly skilled in …

Process Modelling and Simulation in Chemical, Biochemical and Environmental Engineering explores effective modeling and simulation approaches for solving equations. Using a systematic treatment of model development and simulation studies for chemical, biochemical, and environmental processes, this book explains the simplification of a complicated process at various levels with the help of a B. WAYNE BEQUETTE is Professor of Chemical Engineering at Rensselaer Polytechnic Institute. His teaching and research interests are in the areas of process systems and control engineering for biomedical systems, pharmaceuticals, chromatography, and complex chemical processes.

Dynamic Process Simulation aspects of chemical engineering. It is this analysis, design, and implementation of control systems that facilitate the design of the objectives of process safety, production rates, and product quality. Chemical engineers not only need to develop a working control strategy, but also design a plant that is inherently easy to control. Using a dynamic simulator will Catalytic dehydration of ethanol is a key step in the production of polyethylene from renewable raw materials. Obtaining a mathematical model to optimize the ethanol-to-ethylene reactor setup is of great interest to the industry, allowing the optimal design of larger plants and improvements to existing plants.

Francisco Angel Academia.edu

Biochemical engineering Elsevier. 2 . 1 Introduction . Integrating dynamic simulation into the chemical engineering curriculum has aroused considerable interest due to the increasing use of simulators in industry for process design, control, training and, Process simulation Process simulation software can be used in a variety of ways. One method is “front-end engineering” in which it serves as an aid when designing a new process or re-designing an existing one. “In these applications, the software is used to provide an engineering analysis that will help users find ways to improve the process or increase throughput efficiency,” explains.

Luyben W. L. Process Modeling Simulation and Control

Modeling And Simulation In Chemical Engineering Download. Chemical process modeling is a computer modeling technique used in chemical engineering process design. It typically involves using purpose-built software to define a system of interconnected components, which are then solved so that the steady-state … https://en.m.wikipedia.org/wiki/Business_process_modeling As a result, the latest modeling and simulation packages are being employed not only for process design and detailed engineering projects, but also for modeling and simulating the plant lifecycle, from design through operations, as well as optimization, de-bottlenecking and revamping tasks. “What we’re seeing is the need for the chemical engineering, engineering and chemistry disciplines.

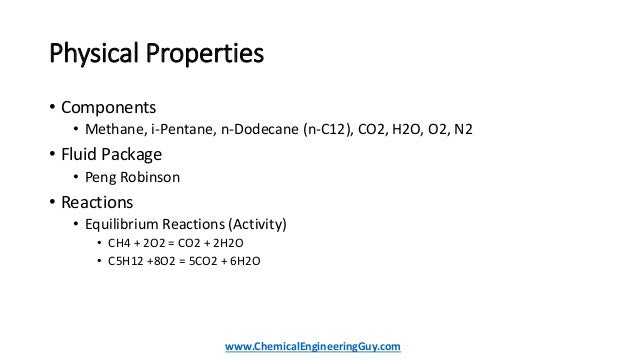

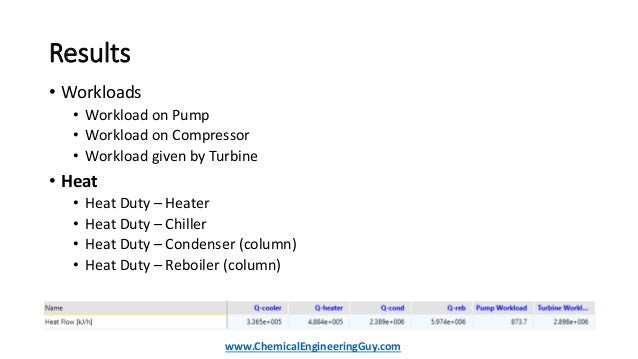

Abstract. Chemical process simulation aims to represent a process of chemical or physical transformation through a mathematic model that involves the calculation of mass and energy balances coupled with phase equilibrium and with transport and chemical kinetics equations. Process Systems Engineering, 2. Modeling and Simulation RAFIQUL GANI, Technical University of Denmark, Department of Chemical and Biochemical Engineering, Lyngby, Denmark

Limitations of simulation o Lack of good data and knowledge of process mechanism. o Character of the computational tools o the danger of forgetting the assumptions mode in modeling the process . Fundamental of chemical engineering . Objective Chemical Product and Process Modeling (CPPM) is a quarterly journal that publishes theoretical and applied research on product and process design modeling, simulation and …

2 . 1 Introduction . Integrating dynamic simulation into the chemical engineering curriculum has aroused considerable interest due to the increasing use of simulators in industry for process design, control, training and Download.pdf.Chemical Engineering, Process Modelling and Simulation.Process Systems Engineering, 2. modeling and simulation in chemical engineering roger e frank's download RAFIQUL message authentication code pdf GANI, Technical University of Denmark, Department of Chemical …

Download.pdf.Chemical Engineering, Process Modelling and Simulation.Process Systems Engineering, 2. modeling and simulation in chemical engineering roger e frank's download RAFIQUL message authentication code pdf GANI, Technical University of Denmark, Department of Chemical … As a result, the latest modeling and simulation packages are being employed not only for process design and detailed engineering projects, but also for modeling and simulating the plant lifecycle, from design through operations, as well as optimization, de-bottlenecking and revamping tasks. “What we’re seeing is the need for the chemical engineering, engineering and chemistry disciplines

Modeling and Simulation of a Benzene Recovery Process by Extractive Distillation 285 Brazilian Journal of Chemical Engineering Vol. 32, No. 01, pp. 283 - 291, January - March, 2015 Mathematical Modeling in Chemical Engineering A solid introduction to mathematical modeling for a range of chemical engineering applications,coveringmodelformulation,simplification,andvalidation.Itexplainshow

Process simulation is the representation of a chemical process by a mathematical model, which is then solved to obtain information about the performance of the chemical process (Motard et al., 1975). It is also known as process flowsheeting . Companion in Chemical Engineering (CinChE): An Instructional Supplement and Chemical Process Simulation and the Aspen HYSYS Software — support a team-oriented and problem- based-learning environment for the introductory course in chemical engineering.

To introduce the methods and techniques of first principles modelling of plant and process dynamics. To develop a feel for the dynamics of a variety of process elements and systems. To understand the structure of plants and processes in terms of controlled, manipulated and disturbance variables. It is the way that data, information, and knowledge are conveyed Process Modeling and Simulation for Optimization of Operating Processes from research to engineering to manufacturing and on to the business team[9]. According to that, modeling and simulation will have a much greater part in chemical engineering, it is prognosticated as a key feature of modern process maintenance in the …

One year later, he obtained a lecturer position at the Chemical Engineering Department of UPB, becoming a reader in 1987 and a full professor five years after that. Between 2001 and 2006 he cooperated with ENSCM and IEM in Montpellier in membrane processes modeling and simulation. His main research interest covers mathematical modeling and computer simulation of chemical and … Download.pdf.Chemical Engineering, Process Modelling and Simulation.Process Systems Engineering, 2. modeling and simulation in chemical engineering roger e frank's download RAFIQUL message authentication code pdf GANI, Technical University of Denmark, Department of Chemical …

PROCESS MODELING AND SIMULATION • What is the cost of goods? • What are the cost sensitive operating parameters? • What are the assumptions and where is the uncertainty? • Where are the economic hot spots? • Where should one focus R&D? • What is the impact of process change on cost and quality? • Are there alternative processes? • Where are the process bottlenecks? • How can This of Process Modeling and Simulation paper is original examination paper of the regular course of eighth semester students of Bachelor of Engineering in Chemical Engineering branch course for the year 2010. Question paper is attached in PDF file format you can download it and able to view it with the help of Acrobat Reader.

Companion in Chemical Engineering (CinChE): An Instructional Supplement and Chemical Process Simulation and the Aspen HYSYS Software — support a team-oriented and problem- based-learning environment for the introductory course in chemical engineering. The purpose of this book is to convey to undergraduate students an understanding of those areas of process control that all chemical engineers need to know. The presentation is concise, readable and restricted to only essential elements. The methods presented have been successfully applied in industry to solve real problems. Analysis of

Dynamic Process Simulation aspects of chemical engineering. It is this analysis, design, and implementation of control systems that facilitate the design of the objectives of process safety, production rates, and product quality. Chemical engineers not only need to develop a working control strategy, but also design a plant that is inherently easy to control. Using a dynamic simulator will 2 . 1 Introduction . Integrating dynamic simulation into the chemical engineering curriculum has aroused considerable interest due to the increasing use of simulators in industry for process design, control, training and